Our partner, COMNET, conducted an interview with Honda Seimitsu Co., Ltd., which has adopted the GCC LaserPro FMC 280 laser cutter and C180II laser engraver. They shared their reasons for choosing our laser machines, their applications, and the benefits they’ve experienced since implementation.

Company Name: Honda Seimitsu Co., Ltd.

Major Business Items: A metal accessories manufacturer supporting from prototyping to final production.

Location: Tokyo, Japan

Facebook

GCC Products: GCC LaserPro FMC 280 Fiber Laser Cutter and C180II Desktop Laser Engraver

What issues did you have before introducing the laser machine?

Our company is a long-established manufacturer of metal accessories, boasting a history of over 60 years since its founding.

We handle every step of the process in-house, from prototyping and design to production and packaging. Even for jewelry with complex designs, if you bring us a single illustration, we can propose how to create it along with a prototype. Additionally, we specialize in creating original mechanical components, such as clasps for watches and necklaces.

While we have handled most machining work using equipment such as machining centers, NC milling machines, and NC lathes, we have relied on outsourcing laser processing for highly complex tasks that are difficult to achieve with these machines.

A long-established manufacturer of metal accessories with over 60 years of history since its founding.

Why introduce the GCC LaserPro laser machine?

We were able to ensure machining precision without the slightest deviation using our existing equipment. However, we realized that a certain segment of our customers places greater emphasis on design over machining precision.

When taking on projects from our customers, I consciously focus not only on addressing their immediate challenges but also on exploring their latent needs. I see this not simply as manufacturing products but as helping each customer unlock their unique potential.

In that sense, laser processing machines are more straightforward tools compared to conventional machining equipment. I began considering their introduction, feeling that laser processing machines could better draw out our customers' individuality and potential.

Given that we frequently worked with titanium, we were introduced to the GCC LaserPro FMC 280, a fiber laser cutting machine well-suited for metalwork. We first requested free samples and then conducted test processing using our preferred materials, thoroughly confirming the quality.

COMNET has extensive experience and a strong support system in selling laser machines in Japan. This made us decide to continue to adopt a GCC LaserPro laser machine.

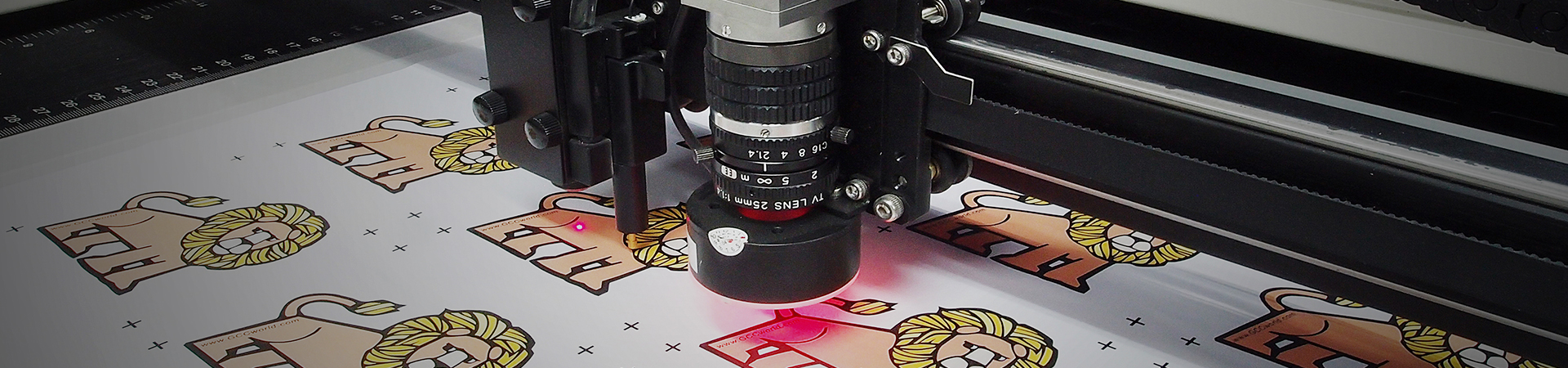

The FMC 280 fiber laser cutting machine is used to cut metal mesh baskets designed for automatic ultrasonic cleaning machines for watches.

What results follow laser machine installation?

Our company collaborates with specialized partner factories in the area to manufacture products and production jigs. Since introducing the laser cutting machine, we have become highly sought after by a wide range of stakeholders, including our partners, clients, suppliers, and even government agencies.

With nearly half a century of experience and achievements in business, we have been able to expand our network significantly. Yet, we feel that the "light" of laser technology has illuminated new hopes for the future.

I will continue working on initiatives such as industry-academia collaborations, striving to shine a bright light on Japan's future and help create a brighter tomorrow.

Only a few companies in Japan, including ours, manufacture metal mesh baskets.

What are your prospects for the laser business?

A significant wave of change has arrived in the manufacturing industry, which forms the backbone of Japan's economy and is predominantly made up of small and medium-sized enterprises.

During the era spanning from the Showa period to the early Heisei era, it was considered a virtue to pour passion into craftsmanship, working overtime without hesitation, and taking pride in product quality. To ensure that the craftsmanship cultivated during this period is passed down securely to future generations, laser engraving and cutting machines have become indispensable tools.

By combining traditional analog techniques with digital equipment, we aim to preserve these heritage methods while introducing creative designs and unique, one-of-a-kind products to the world.

The acrylic bangle is crafted using the compact C180II laser engraving machine. The process involves laser cutting acrylic sheets, followed by bending and polishing.

To read the original article, please click here.

*Please refrain from reproducing or distributing this article without obtaining permission from GCC.

Introduced laser engraving machine:

We are happy to answer your questions about any laser products and processing. If you want to learn and do more with GCC LaserPro lasers, we invite you to see our laser engraving and cutting applications videos where you will find out how they physically work and are done.

Further reading:

➤ 2024 Top-Quality GCC Laser Cutters & Cutting machines

➤ Discover the Power of Laser Engraving

➤ How To Make Laser Engraving Darker on Stainless Steel