We had the opportunity to interview U-Media, which initially used the GCC LaserPro E200 and later introduced the Spirit LS laser engraving machine. They shared insights into what motivated them to adopt this technology, its various applications, and the benefits they have gained since its installation.

Company Name: U-Media Co., Ltd.

Major Business Items: Advertising/printing, sales promotion, media/event management.

Location: Miyagi, Japan

Facebook

GCC Products: GCC LaserPro desktop E200 40W and Spirit LS 40W Laser Engraver

What issues did you have before introducing the laser machine?

Our company, U-Media, based in Sendai City, Miyagi Prefecture, is involved in advertising, printing, publishing, web production, app development, event planning and management, local media management, regional revitalization and tourism development, branding, and sales promotion, among other services. As a "Communication Design Company," we address challenges faced by our clients and the local community in Sendai, Miyagi, and the Tohoku region. Through communication design, we develop and implement a wide range of initiatives to provide effective solutions.

The idea to consider a laser engraver originated from the development of paper charm accessories. As part of our in-house initiative called the "New Value Creation Project," a proposal came from Iwamoto, a female employee in the Planning Team of our Sales Center. She suggested creating paper charm accessories.

The initial concept involved offering the product in the form of a postcard, allowing customers to cut out the charms themselves using scissors. However, during a pre-sale event, we received significant feedback requesting pre-cut products. This feedback highlighted the need for a machine capable of efficiently cutting paper to bring the concept to life.

During a private showcase hosted by a distributor, we first encountered a laser engraver. Seeing its ability to cut paper precisely, we realized it could add significant value to the product, which led us to seriously consider introducing the technology.

Paper charm accessories “kamimi"

Why introduce the GCC LaserPro laser machine?

When we began searching for a laser engraver, we were introduced to E200 (also known as MAKES in Japan), a subscription-based laser engraver. Within the company, there was a consensus that it was "perfect for startups," leading to the decision to adopt it. After seeing a demonstration of the E200 in action and confirming that it posed no operational issues, we moved forward with the implementation with confidence.

The first machine installed was the E200 desktop laser engraver, chosen in part for its availability on a subscription basis.

The workshop uses E200 laser engraver to quickly turn ideas into reality, such as by scanning a child's drawing and processing it with a laser, delighting customers with instant results.

Replacement with Spirit LS laser engraver?

After introducing the E200 desktop laser engraver in February 2022, we upgraded to a mid-sized model, the Spirit LS, in September 2023.

E200 was initially positioned as a "trial" solution to support the business until it gained traction, and we used it for about a year and a half. However, it turned out to be far more than just a trial, as it was heavily utilized during that time. With the business growing steadily and reaching a stage of further expansion, we decided to invest in a production-grade laser engraver.

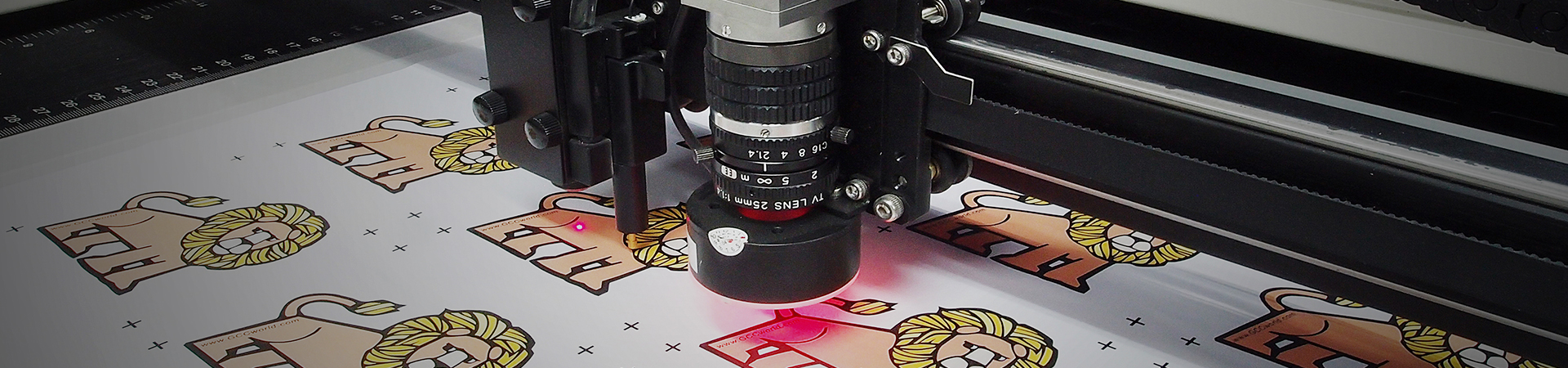

The key reasons for choosing the Spirit LS included its ability to significantly enhance production speed and processing quality, as well as its CCD camera, which makes alignment much easier. Additionally, the larger working area and capability to process long or tall materials were decisive factors in the upgrade.

Introduced machine: GCC LaserPro Spirit LS, a mid-size laser engraving machine to replace the E200.

What results follow laser machine installation?

The paper charm accessories “kamimi”, which inspired the introduction of the laser engraver, is sold as an accessory that allows customers to assemble pre-cut parts.

The ability to laser-cut intricate shapes has increased the product's visibility, drawing more attention from customers. This, in turn, seems to have motivated the production team further.

Additionally, the capability to quickly turn concepts and ideas into tangible products has been a significant benefit. Bringing product samples directly to clients has made proposals more compelling, facilitating smoother project progression and product development. In workshops, customers are delighted when their ideas are transformed into products on the spot.

The laser engraver has also contributed to cost reduction. By bringing the process in-house, we have cut outsourcing expenses and reduced overall production costs.

Decorative parts for wild birds in the exhibition space using laser engraving and UV printing.

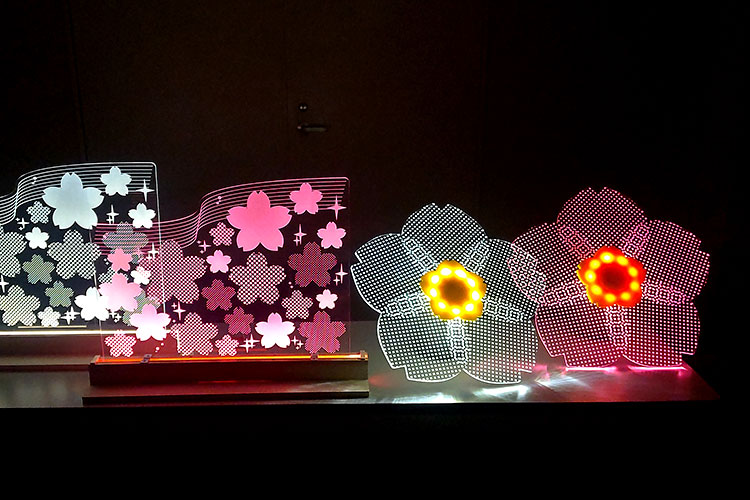

LED light guide plate installed at the event space, with laser-engraved areas emitting light when illuminated from the edge of the acrylic board.

What are your prospects for the laser business?

We aim to leverage laser engraving and UV printing to expand our business operations. While our focus is primarily on processing paper and acrylic, we are also eager to experiment with leather products and broaden our product lineup. One exciting idea is to create a mobile workshop by equipping a kitchen truck with a laser engraver. This could serve as a traveling workshop for events, offering an unique and interactive experience.

Sendai is well-known for its iconic "Zelkova Tree-lined Streets." However, some of these trees have aged and are occasionally felled to prevent hazards. Utilizing this reclaimed wood to create products unique to Sendai could contribute to SDG initiatives while showcasing the city's charm.

By fully utilizing the versatility of our laser engraver to process various materials, we hope to craft original products and plan events that reflect the unique identity of our company.

To read the original article, please click here.

*Please refrain from reproducing or distributing this article without obtaining permission from GCC.

Introduced laser engraving machine:

We are happy to answer your questions about any laser products and processing. If you want to learn and do more with GCC LaserPro lasers, we invite you to see our laser engraving and cutting applications videos where you will find out how they physically work and are done.

Further reading:

➤ Discover the Power of Laser Engraving

➤ Glass Laser Engraving Guide: Tips and Tricks

➤ Laser Cutting Precision, Versatility, and Applications