We interviewed Mr. Shingo Hamaya, President of Hamaya Co., Ltd., and Ms. Yui Takemoto from the Manufacturing Department, who have introduced the GCC LaserPro SPIRIT GLS 80W laser engraver. They shared with us the reasons for introducing the laser engraving machine, its applications, and the benefits they have experienced since its installation.

Company Name: HAYAMA Co., Ltd.

Major Business Items: Manufacture and sale of natural wood veneer laminated panels

Location: Osaka, Japan

Facebook

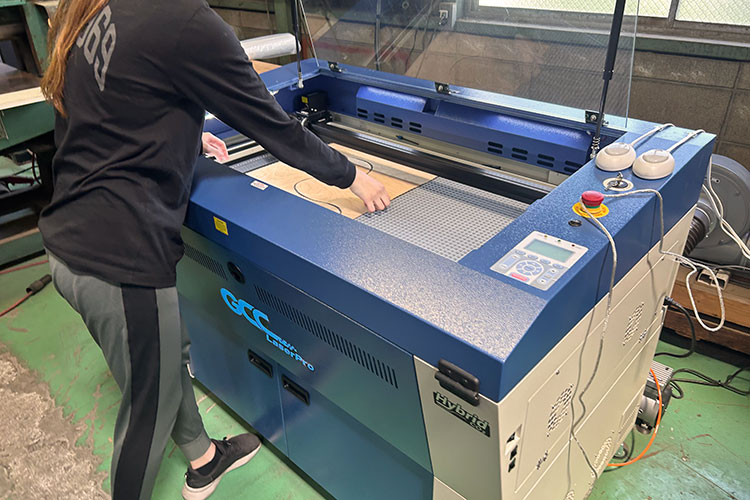

GCC Products: GCC LaserPro Spirit GLS 80W Laser Engraver

What prompted you to introduce the GCC LaserPro laser machine?

HAYAMA Co., Ltd. manufactures and sells natural wood decorative boards. Natural wood decorative boards refer to materials where a veneer of natural wood, sliced to about 0.2 millimeters thick, is laminated onto plywood or similar substrates.

This material combines the beautiful grain and texture of natural wood with the ease of processing and cost-efficiency of plywood, making it suitable for various applications.

With traditional cutting machines, materials could only be cut in straight lines, limiting the scope of design possibilities. However, some of our customers require decorative boards with veneer laminated in complex shapes. We addressed this through manual cutting, but the dimensional accuracy was inconsistent, and the cutting and lamination processes took a significant amount of time.

Natural wood veneer sliced to a thickness of about 0.2 mm is glued onto plywood or other materials.

Natural wood veneer manufacturing factory

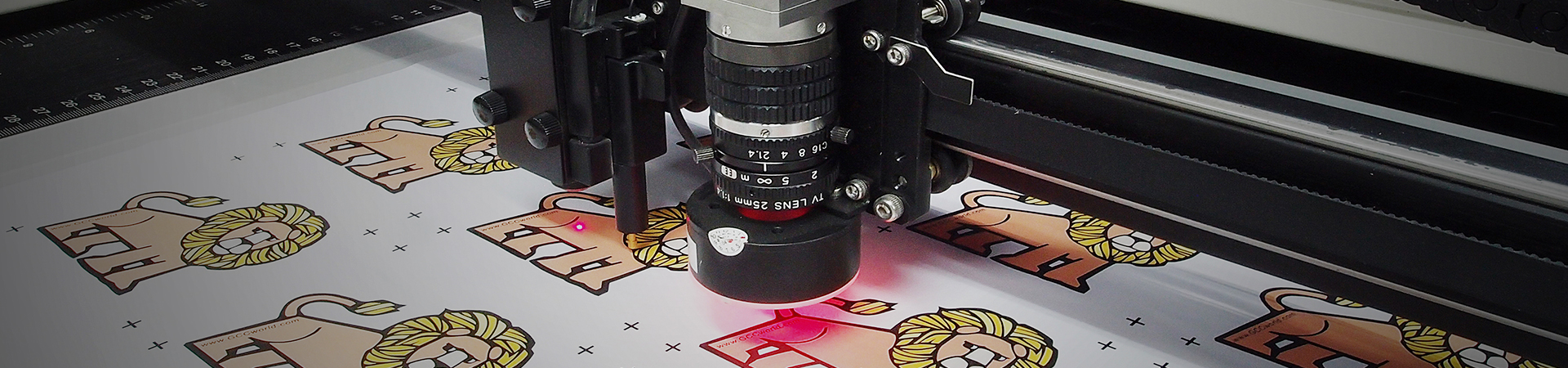

Cutting machine for cutting tsuki plates

Normal straight cuts are made with a cutting machine, but complex shapes are handled manually.

What are you using the laser cutting machine for?

I had known about laser engraving machines for some time through the email newsletters from COMNET. As we started receiving more orders and inquiries for decorative boards with complex shapes, we consulted with them about introducing a laser engraving machine.

Based on our requirements for a machine with a processing area of at least 600×450mm that could accurately cut veneer with a thickness of 0.2–0.5mm, we were recommended and decided to install the GCC LaserPro Spirit GLS medium-sized CO2 laser engraving machine.

We were initially concerned that laser cutting might cause burn marks on the veneer edges, but by testing sample cuts, we were able to determine the optimal settings, confirming that there would be no issues. The processing area is also 960×610mm, and the space can be further expanded when the door is open, which was another major advantage. While the main use is for cutting veneer, it can also be widely utilized for long materials and other needs.

The fact that we could reduce the installation cost with subsidies was also a key factor in our decision.

Additionally, the graphic software for editing the processing data is intuitive to use, allowing us to respond flexibly to the designers' requests. It’s reassuring to know that we can receive support from COMNET whenever we face operational difficulties.

Initially, we only envisioned cutting veneer, but we were pleasantly surprised to learn that a wide variety of materials could be cut. We are excited to explore new possibilities, such as combining them with veneer, in the future.

Installed machine: Laser engraving machine GCC LaserPro Spirit GLS

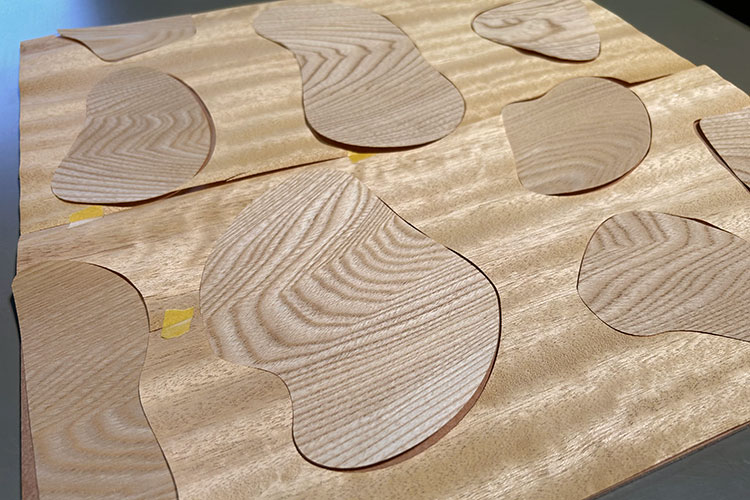

Utilizing a laser cutting machine to cut intricately shaped wood planks

What results follow laser machine installation?

With the introduction of the laser engraving machine, we are now able to cut complex shapes quickly and accurately, significantly reducing the time required for cutting and lamination. Compared to manual work, the processing time has been cut by about half.

Curved laser-cut wood planks

Significant time savings compared to manual cutting.

Laminated panels with complex shapes and originality can lead to differentiation.

What are your prospects for the laser business?

We will continue to work on providing better decorative boards by combining various natural wood grains and colors. Additionally, since the laser engraving machine can also handle other materials like paper and fabric, we are exploring the possibility of matching these different materials with decorative boards to develop original products.

To read the original article, please click here.

*Please refrain from reproducing or distributing this article without obtaining permission from GCC.

Introduced laser engraving machine:

We are happy to answer your questions about any laser products and processing. If you want to learn and do more with GCC LaserPro lasers, we invite you to see our laser engraving and cutting applications videos where you will find out how they physically work and are done.

Further reading:

➤Laser Cutting Precision, Versatility, and Applications

➤2024 Top-Quality GCC Laser Cutters & Cutting machines

➤Materials Compatible for Laser Engraving, Cutting & Marking