Mr. Katsuya Shiromizu from the Planning and Development Department of TAKANO Woodworking Co., Ltd., has adopted our GCC LaserPro C180II laser engraving machine. He graciously shared with us the reasons for introducing the laser machine, its uses, and the benefits they have experienced from its implementation.

Company Name: TAKANO Woodworking Co., Ltd.

Major Business Items: Planning, manufacturing, and sales of household furniture

Location: Fukuoka, Japan

Facebook

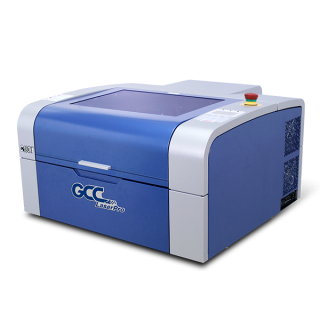

GCC Products: GCC LaserPro C180II laser engraver (30W)

What issues did you have before introducing the laser machine?

Our company began in 1942 in Okawa City, Fukuoka Prefecture, renowned as the "City of Furniture" for its leading furniture production in Japan. We started with the production of chests and have since dedicated ourselves to creating furniture with "timeless designs" that can be used safely and reliably for a long time. In 2022, we celebrated our 80th anniversary. We have directly operated stores in Tokyo, Osaka, and Fukuoka, and our products can be seen and touched at partner shops nationwide.

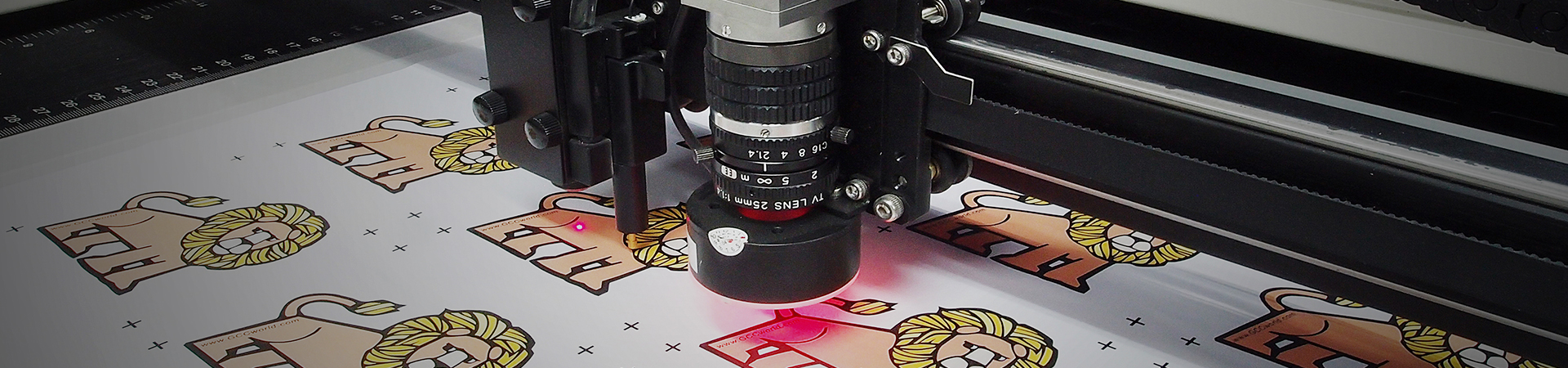

In furniture manufacturing, wood processing is mainly done using woodworking machines (such as NC routers and presses). We outsourced the laser engraving of text and logos (like company name signs used at exhibitions), since most orders were for single items or small lots, the outsourcing costs were understandably high.

Seeing an increase in engraving orders, we considered in-house production to cut costs. Additionally, just as with our furniture making, the desire to "create unique signs, displays, and signage in-house" was one of the motivations for introducing a laser engraving machine.

Home furniture manufactured and sold by TAKANO.

Why introduce the GCC LaserPro laser machine?

We were looking for a laser engraving machine that could finely and neatly engrave the types of wood we use in furniture manufacturing (such as alder, walnut, and white oak). When we looked at Comnet's website, we felt, "This is a reliable company," and decided to inquire further.

The laser engraving machine we introduced, the GCC LaserPro C180II, can process up to A3 size, yet it is compact and doesn't take up much space. We were attracted by its ability to cut and engrave wood at a high level. Additionally, we felt confident about the support aspect, which made us feel assured in making the decision to introduce it.

What results follow laser machine installation?

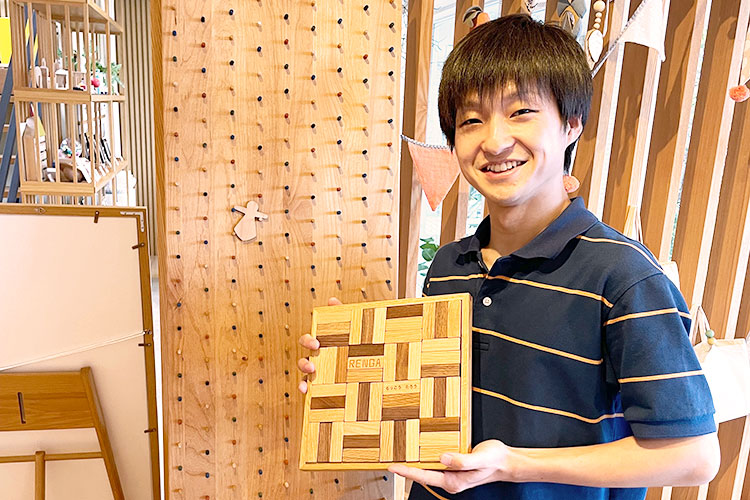

Since introducing the laser engraving machine, our monthly sales have increased by 10%. The range of things we can do has significantly expanded, broadening our scope of work.

For example, we can now offer services such as engraving names on small items and wooden toys, which have been well received by our customers. The ability to address challenges that were impossible with outsourcing has accelerated our product development and increased the number of items in our lineup.

Product logos and names are engraved using C180II.

Situations where the laser engraving machine is utilized

We frequently use the laser to engrave logos of our company name and product names. This includes signs used at exhibitions and showrooms, craft kits for workshops, and toys made from scrap materials.

We often use alder wood (from the birch family). We also frequently use veneered MDF, which is easy to process.

Katakata dolls being made in the workshop

Laser engraved product logo on the back side

We regularly hold workshops to make wooden toys for children

Click here for details on the workshops

What are your prospects for the laser business?

The furniture manufacturing process generates a lot of wood and MDF scraps, so I would like to develop small items and toys that make use of the scraps.

Currently, one person is in charge of everything from creating and processing data to laser processing, which is not efficient. I would like to share the operating instructions with other employees to increase production efficiency.

We mainly process MDF, wood, and acrylic, but the laser engraving machine can handle a wide range of materials, so we would like to expand our work to other materials as well.

To read the original article, please click here.

*Please refrain from reproducing or distributing this article without obtaining permission from GCC.

Introduced laser engraving machine:

We are happy to answer your questions about any laser products and processing. If you want to learn and do more with GCC LaserPro lasers, we invite you to see our laser engraving and cutting applications videos where you will find out how they physically work and are done.

Further reading:

➤Discover the Power of Laser Engraving

➤Materials Compatible for Laser Engraving, Cutting & Marking

➤Tips and Tricks: Acrylic Cutting with Your Laser Engraver and Laser Cutter