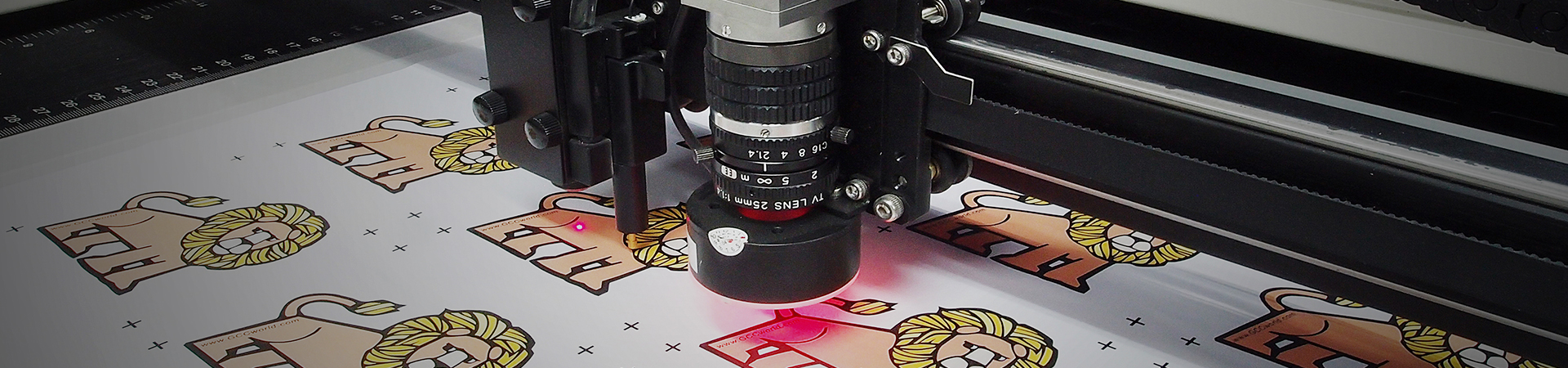

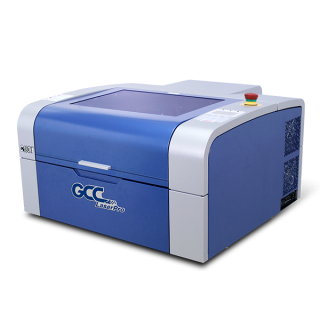

| Our partner, COMNET, interviewed Mr. Tsufuku Masatoshi from the desk A&R Products Creative at BadeggBox Co., Ltd, who has introduced the GCC LaserPro C180II (30W) laser engraver. He shared with us the reasons for introducing our laser engraving machine, its applications, and the benefits of its implementation. Company Name: BadeggBox Co., Ltd What issues did you have before introducing the laser engraving machine?We operate the music label 'BadeggBox.' Since we're already in the music industry, we thought it would be interesting to create our guitar picks and merchandise for instruments. Before introducing machinery, we outsourced all our merchandise production. However, dealing with different suppliers for each item, coordinating various meetings, exchanging data, and adjusting delivery times consumed a lot of time. We believed that by internalizing the process, we could reduce our interactions with external suppliers. Additionally, the appeal of being able to handle everything from idea to design and production internally seemed highly attractive. Hence, we started considering the introduction of machinery.  Installed model: Laser engraving machine GCC LaserPro C180 II. What are the reasons and main considerations for introducing the laser machine?Ten years ago, we introduced the desktop laser engraving machine GCC LaserPro C180 (the previous model of the current C180II). Initially, for merchandise production, we decided to introduce a UV inkjet printer. However, we received a suggestion that 'fixtures for securing materials are indispensable for printing' and 'creating fixtures with a laser engraving machine would lead to cost savings.' Therefore, we decided to introduce the laser engraving machine along with it. In April 2023, after ten years of service, the first C180 reached the end of its life as the laser tube expired. We replaced it with the successor model, the GCC LaserPro C180II. There were some minor specification changes, but overall, the functionality remained the same. The size of the main body also remains suitable, not occupying too much space, which we find just right.

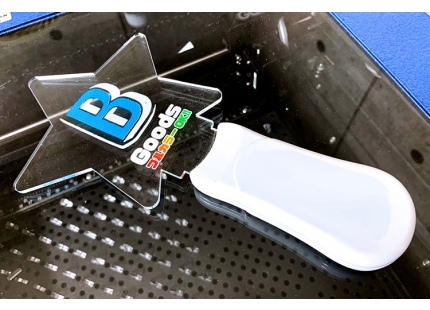

What results follow laser machine installation?Having the capability to manufacture our own products, we were excited to bring products conceived from our ideas directly to our customers, and thus, we commenced the sale of these items. We specialize in creating unique products for our musician customers, including a variety of acrylic items like keychains, stands, and LED lights, as well as custom pickguards for musical instruments. Our expertise extends to engraving intricate designs on wooden plaques and coasters. In the early stages of our introduction, acrylic keychains and stands were not as prevalent as they are today. We began with a hands-on, exploratory approach, seeking to discern customer preferences and establish fundamental specifications for these products. A decade on, we persist in leveraging our manufacturing prowess for the production of products. Our sustained success is attributed to our ability to produce in small quantities with rapid turnaround times, coupled with the capacity to instantaneously transform concepts into tangible products. I believe there is no substitute for the speed and quality maintenance that comes with in-house production.

What are your future prospects for the laser business?Since acrylic processing has become more prevalent, we would like to explore ideas utilizing materials such as leather, paper, fabric, and resin, in addition to wood products other than wooden plaques and wooden coasters. We aim to expand our product range and develop new ideas in these areas.

Introduced laser engraving machine:We are happy to answer your questions about any laser products and processing. If you want to learn and do more with GCC LaserPro lasers, we invite you to see our laser engraving and cutting applications videos where you will find out how they physically work and are done. Further reading:➤Exploring the Versatility of Laser Engraving: Capabilities and Materials |

Quick, diverse production with C180 II Laser Engraver

English

Success Story