Using Advanced Shoulder Level to Create your Own Stamp | GCC: Laser Machines Leader Since 1989

Stamp engraving is a very common application of laser. Laser is utilized to engrave soft rubber to produce fine words and figures. After cleaning the engraved rubber, adhere it to a handle and then a unique product is produced. Rubber stamps like this are customized commercial products that are frequently asked. In this issue of Show Case, GCC LaserPro Application Lab would like to introduce you a suggested procedure to increase the quality of the engraved rubber by utilizing the additional features of the Laser Engraver. The produced stamps will have better performance and more elegant overall appearance.

Production procedure

Step 1. Download the CDR file that LaserPro prepared for you.

Step 2. Put the rubber into the machine for the engraving.

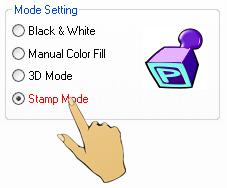

Step 3. Select Stamp Mode in the Driver.

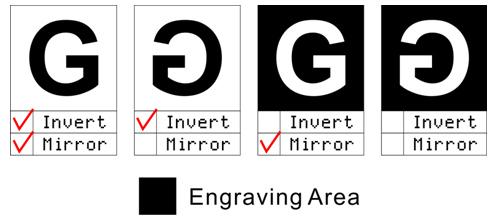

Step 4. Select Invert and/or Mirror functions according to the desired effect.

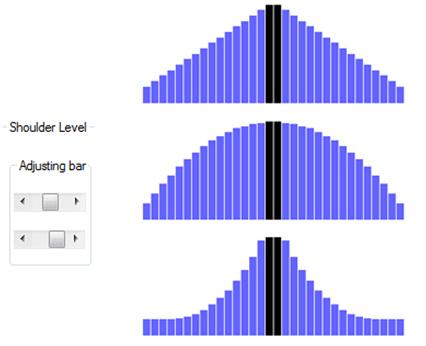

Step 5. Select Shoulder Level in the Stamp Mode.

* When stamping, if the rubber doesn’t have enough structure strength, it will cause a rubber distortion; therefore, Shoulder is a necessary function for stamp engraving.

The distortion phenomenon occurs without using Shoulder function.

Step 6. Press the Auto Focus button on the panel to adjust the focus after finishing the foregoing settings

Step 7. Press the Start button to begin the engraving.

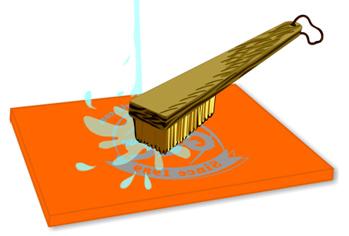

Step 8. Clean the engraved rubber with clean water and brush.

Sample:

Suggested Parameters:

Spirit 30W | |||||

Speed | Power | DPI | ppi | Mode | Other |

15 % | 100 % | 600 | 400 | Stamp Mode | Air Assist |

Spirit 60W | |||||

Speed | Power | DPI | ppi | Mode | Other |

25 % | 100 % | 600 | 400 | Stamp Mode | Air Assist |

Tips:

- Turn on air assist during engraving to prevent the lens from being contaminated due to ignition.

- Please double check whether the Mirror function is selected. Otherwise the stamp would produce the mirror image of the desired effect.