DTF Transfer to Glass and Ceramic Creamer Pot Applications | GCC: Laser Machines Leader Since 1989

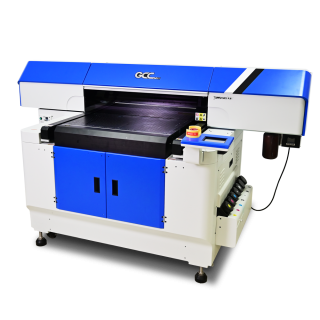

This month, the GCC JF-2418UV application laboratory specially introduces the technical application of DTF (Direct-to-Film) on glass and ceramic creamer pot.

GCC JF-2418UV collocates with PVC backing film and laser film material to make DTF application by adopting high-efficiency direct inkjet printing technology, which sprays color and transparent ink at the same time to produce fast and accurate tactile printing. The technology can be used for different design contents such as numbers, letters, symbols, and image designs to create textured effect on designated area, highlighting the delicate quality of the goods. It can be produced in a small amount with variety without the need for plate making.

The GCC JF-2418UV directly prints on PVC backing film and laser film, transfer the print image to glass or ceramic creamer pot, and then tear off the film to complete the sample, which create great quality and high value added products with simplified process.

The final sample images are as follows

|  |

|  |

Suggested parameters:

| Material | Print Mode | Print Color | Directional | LED | Pre-Coat | Top-Coat |

| Glass | High Density | YMCK+Pr | Bi-Directional | 100% | Y | N/A |

| Creamer bottle | High Density | YMCK+Pr | Bi-Directional | 100% | Y | N/A |