Create a UID Mark by Laser Engraver / Marker | GCC: Laser Machines Leader Since 1989

Unique Identification or IUID, is a part of the compliance process mandated by the United States Department of Defense. It is a permanent marking method used to give equipment a unique ID. UID-marking is a set of data for assets that is globally unique and unambiguous.

The technology used to mark an item is 2D Data Matrix ECC 200 Symbol. UID marking can be used to ensure data integrity and data quality throughout an item's lifecycle; it also supports multi-faceted business applications.

Procedures:

Laser Engraver Series

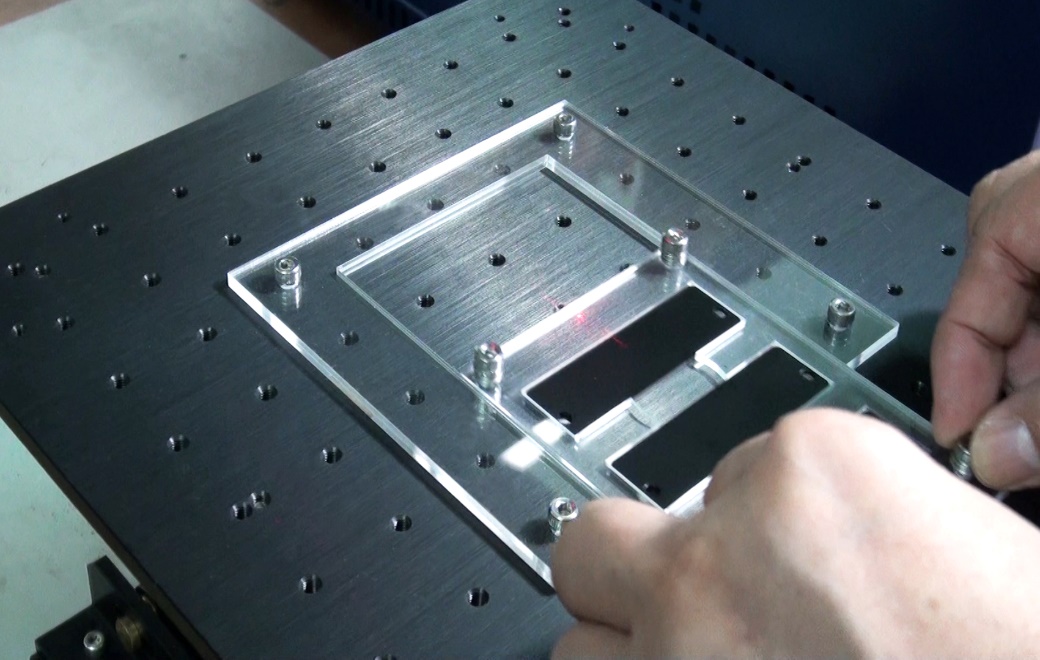

Step 1. Put the materials/objects that need to be processed on the platform

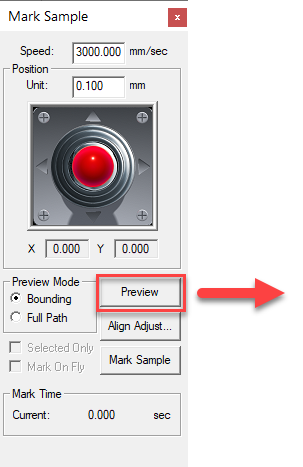

Step 2. After setting the parameters, press the preview button to determine the processing

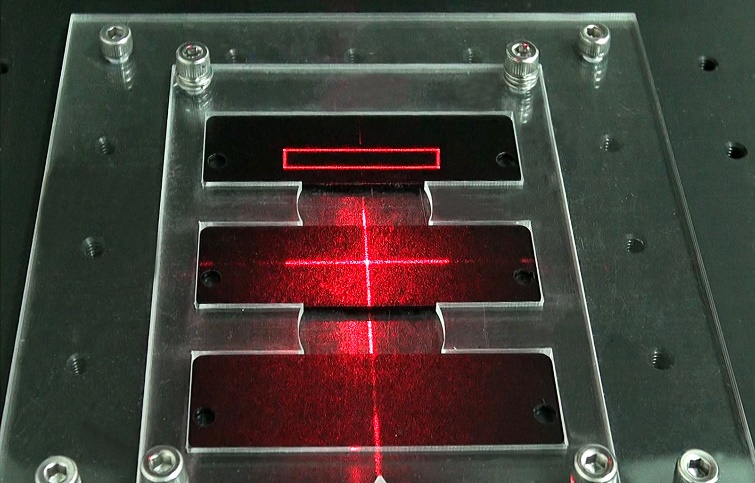

Step 3. Press the Exec button to do marking

Step 4. Sample is complete.

Suggested parameters:

Black Nameplate Marking

| Frame / Fill | |||

|---|---|---|---|

| Frame | Fill | Border | Pitch |

| X | V | 0 | 0.03 |

| Times | Two way | Angle start | Angle Step |

| 1 | V | 0 | 0 |

| Mark Parameter | |||

| Speed | Power | Frequence | Times |

| 2000 mm/s | 60% | 30 kHz | 2 |

| Laser Shot | |||

| 1 | |||

| 2D Marking | |||

| Style | A | B | Laser Shot |

| Spot - Orderly | 0.01 mm | 0.02 mm | 1 |

| Delay | |||

| Start point delay | Mid point delay | End point delay | Mark delay |

| 0 ms | 0.1 ms | 0.3 ms | 0.3 ms |

| Jump speed | Delay | ||

| 1000 mm/s | 0.5 ms | ||

Tools Marking

| Frame / Fill | |||

|---|---|---|---|

| Frame | Fill | Border | Pitch |

| X | V | 0 | X |

| Times | Two way | Angle start | Angle Step |

| 1 | V | 0 | 0 |

| Mark Parameter | |||

| Speed | Power | Frequence | Times |

| 100 mm/s | 100% | 60 kHz | 4 |

| Laser Shot | |||

| 1 | |||

| 2D Marking | |||

| Style | A | B | Laser Shot |

| Spot - Orderly | 0.01 mm | 0.02 mm | 1 |

| Delay | |||

| Start point delay | Mid point delay | End point delay | Mark delay |

| 0 ms | 0.1 ms | 0.3 ms | 0.3 ms |

| Jump speed | Delay | ||

| 1000 | 0.5 | ||

*The parameters are for suggestions only and should be moderately adjusted accordingly.

Tips: Please ensure that the material is flat before processing to avoid material damage caused by defocus.