Laser Engraving Machine for Metal Guide

IG:@kreative_lasergravuren

Laser engraving on metal has become an essential technique for industries seeking precision and durability in their engravings. From intricate designs to serial numbers, laser engraving leaves a permanent mark without damaging the metal. This guide explores the basics of choosing a laser engraving machine for metal, including how it works, its benefits, and its diverse applications.

Overview of Laser Engraving Technology

How Laser Engraving Machines Work

Benefits of Laser Engraving on Metal

Types of Metal Suitable for Laser Engraving

Applications & Techniques for Laser Engraving on Metal

High Quality Metal Laser Engravers Recommended

Conclusion

Overview of Laser Engraving Technology

Laser engraving technology relies on a concentrated light beam to etch designs and engravings onto metal surfaces, achieving incredible precision and clarity. This process doesn’t require physical contact, which minimizes wear on the material while producing a permanent, clean finish. A laser engraving machine for metal can mark everything from intricate designs to barcodes and serial numbers, making it an ideal choice for applications requiring detail and durability.

Industries such as aerospace, medical equipment, automotive, and consumer goods regularly use laser engraving to ensure high-quality, lasting impressions. The adaptability of laser engraving also allows it to handle various metals, such as stainless steel, aluminum, titanium, and more, without compromising the material’s integrity. Thanks to the speed and flexibility of this technology, businesses can achieve consistent results across a range of applications, from product branding to industrial engraving, making laser engraving an indispensable tool across sectors.

How Laser Engraving Machines Work

Laser Engraving Process Explanation

A laser engraving machine for metal uses a concentrated light beam to remove material from the surface, creating precise engravings without touching the metal directly.

The machine’s laser focuses on a specific point, generating intense heat that vaporizes or melts the material in controlled patterns. Through this, intricate designs, logos, or text can be etched into the metal.

The depth of engraving is adjusted by the laser’s intensity, speed, and focus, allowing for anything from shallow marks to deeper engravings, all with minimal heat impact on surrounding areas.

Types of Laser Engraving Machines

Different types of laser engraving machines are available to suit various metal engraving needs, with fiber and CO₂ lasers being the most common:

- Fiber Lasers:Known for their durability and efficiency, fiber lasers work well with metals like stainless steel, aluminum, and brass. They deliver a concentrated laser beam ideal for high-contrast engravings and are favored for their low maintenance.

- CO₂ Lasers:Though primarily used on non-metallic surfaces, some CO₂ lasers can engrave treated metals, such as coated tumblers or anodized aluminum. Additionally, by using pre-applied compounds for laser engraving, CO₂ lasers also can process uncoted metal but the result is not permanent (Could be scratched off easily).

Each type offers different strengths, making it essential to select the right machine based on the project’s material and design requirements. Fiber lasers generally outperform CO₂ for metal engraving due to their precision and reliability with hard surfaces.

Benefits of Laser Engraving on Metal

High Precision and Detail

A laser engraving machine for metal achieves remarkable accuracy, allowing for intricate designs, logos, and detailed text, even on small surfaces. The laser's fine control creates sharp, clear engravings without smudging or blurring, making it ideal for serial numbers, branding, and custom patterns.

This high level of detail enhances the quality of the finished product, providing professional results that can withstand scrutiny.

Non-Contact Process

Laser engraving is a non-contact process, meaning the laser beam touches only the surface it engraves without physically impacting the metal. This approach minimizes the risk of scratches, dents, or other damage to the material, preserving its structural integrity.

It’s particularly beneficial for metals that require durability, as the process doesn’t weaken or deform the material.

Versatility in Design and Application

Laser engraving offers incredible flexibility, handling a wide range of designs, from simple text to complex graphics. A laser engraving machine for metal can accommodate different styles and depths, supporting everything from shallow surface marks to deep engravings.

This versatility allows businesses to adapt the technology for industrial parts, consumer branding, and decorative uses, making laser engraving a versatile tool across multiple industries.

Types of Metal Suitable for Laser Engraving

Common Metals Used

A laser engraving machine for metal can work effectively on various metals, including stainless steel, aluminum, brass, and titanium.

Each of these metals is durable, resistant to corrosion, and capable of holding intricate designs, making them popular choices for industries that require precise engravings.

Stainless steel and aluminum are frequently used in industrial applications, while brass and titanium find use in decorative and medical devices.

Characteristics and Suitability

Each metal offers distinct properties for laser engraving.

Stainless steel, for example, is durable and provides excellent contrast, while aluminum is lightweight and engraves quickly.

Brass is often used for its aesthetic appeal, giving a polished, elegant look.

Titanium, meanwhile, is corrosion-resistant and compatible with high-precision work, suitable for medical tools and high-tech applications.

Choosing the Right Metal

Selecting the appropriate metal for laser engraving depends on the project’s requirements.

For durability and high contrast, stainless steel is ideal.

If lightweight, fast engraving is needed, aluminum is a solid choice.

For projects requiring decorative appeal, brass works well.

Understanding the specific properties of each metal ensures optimal results from a laser engraving machine.

Applications & Techniques for Laser Engraving on Metal

Applications

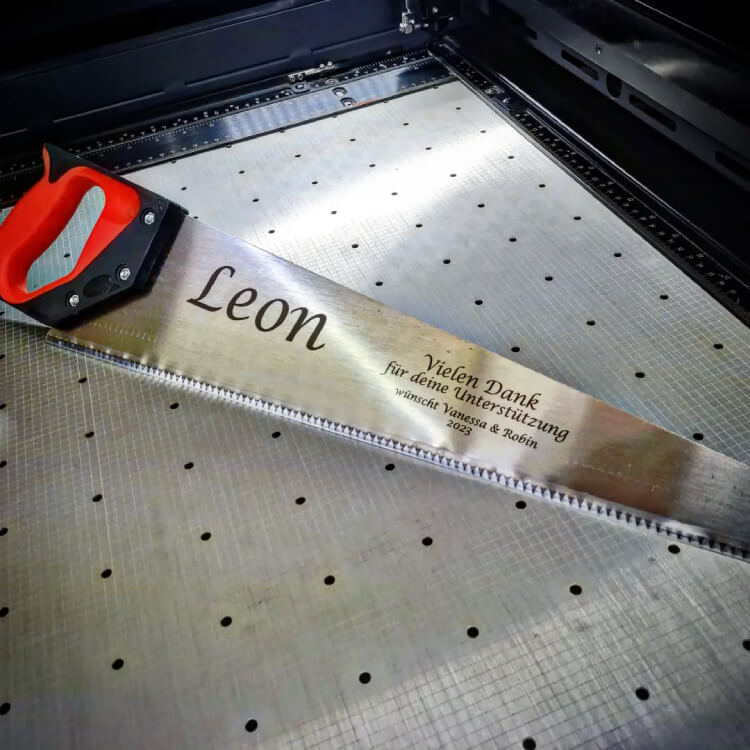

A laser engraving machine for metal has diverse applications across industries. In manufacturing, it’s used for part identification, serial numbers, and barcoding.

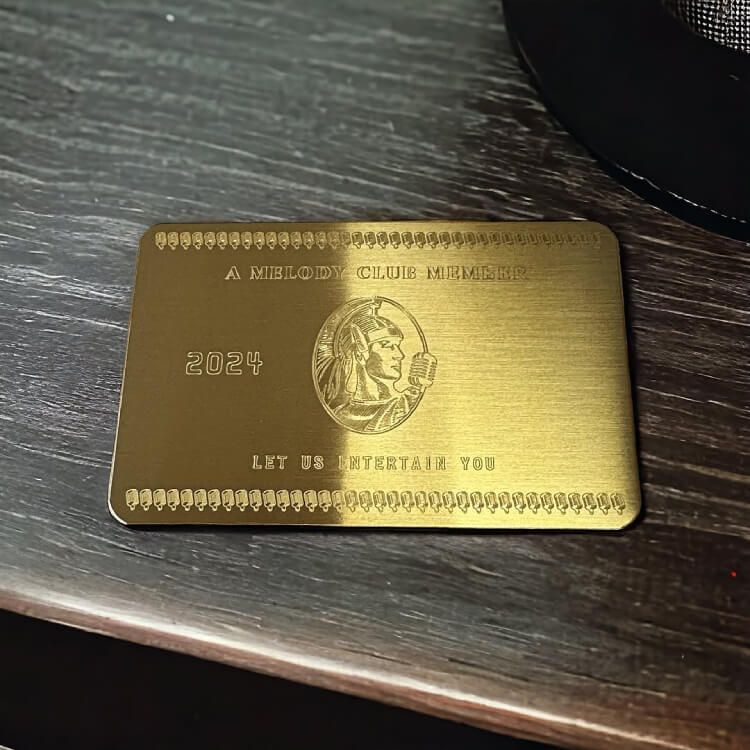

Consumer products, from jewelry to electronics, benefit from laser-engraved branding and customization.

Companies also use laser engraving for promotional items like metal pens, keychains, and plaques.

Additionally, artistic and decorative industries rely on laser engraving to create intricate designs on metals for displays and collectible items.

Deep Engraving vs. Surface Engraving

Laser engraving on metal can achieve both deep engraving and surface engraving, depending on the project’s requirements.

Deep engraving involves removing more material, creating a durable and tactile mark ideal for heavy-duty applications and pieces exposed to wear.

Surface engraving, by contrast, creates a shallower impression, mainly altering the metal's color without affecting its depth. This technique works well for applications needing high-contrast visuals without the need for deep cuts.

Special Effects Techniques

Various laser engraving techniques can produce distinct visual effects on metal:

- Dark Engraving:Using a defocused mode without removing material, this technique creates darker color changes. Dark engraving is commonly used to produce black, high-contrast engravings on stainless steel.

Learn more: How To Make Laser Engraving Darker on Stainless Steel

- Color Engraving:Some laser engraving machines can create colored marks on metal by controlling the laser’s intensity and speed. This technique is typically used on materials like titanium to produce vibrant effects, adding an aesthetic appeal to items like jewelry.

Learn more: Multiple Waveforms of GCC LaserPro Fiber Laser Machines

Each technique allows customization, enabling businesses to achieve the desired appearance and functionality in their engraved products. Discover more metal laser engraving applications here!

High Quality Metal Laser Engravers Recommended

When it comes to selecting a laser engraving machine for metal, GCC LaserPro offers three exceptional options, each designed to meet different engraving needs and applications:

The GCC LaserPro Spirit LS PRO combines advanced technology with user-friendly features, making it ideal for industrial, architectural, and signage applications. With CO₂ and fiber laser options, a 29” × 18” working area, and 30W or 50W power, it excels in engraving metals, plastics, and more.

A 4-inch touch panel offers intuitive control, while SmartEYES™ CCD enables effortless material positioning. Pass-through doors handle larger projects, and the SmartPIN™ Auto Focus system ensures precise setup in seconds. SmartLID™ simplifies maintenance, and a magnetic measuring ruler caters to both metric and imperial preferences.

Designed for efficiency, its enhanced driver UI boosts workflow, delivering consistent, high-quality results. Whether for text, logos, or barcodes, the Spirit LS PRO is a reliable choice for professionals seeking precision and profitability.

The S400 is a high-performance laser engraver known for both speed and precision.

It features a 140ips high-speed DC servo motor, enabling precise and rapid movement of the laser carriage. This not only saves users time and costs but also boosts productivity.

GCC LaserPro innovative SmartFLOW Technology enhances airflow to create a powerful vacuum effect, effectively removing dust during operation. With an extra-large 40” x 24” working area, the S400 delivers 100% engraving quality even at maximum speed, ensuring the highest throughput and exceptional laser precision.

The S400's dual-laser technology eliminates the need for optics changes or manual adjustments during laser switching. It supports fiber wattages of 20W, 30W, and 60W and CO₂ wattages ranging from 30W to 120W, making the S400 Hybrid ideal for engraving, cutting, and engraving on both organic materials and metal simultaneously.

The Spirit GLS Hybrid is a versatile machine that combines CO₂ and fiber laser technology in one, allowing users to engrave both metals and various non-metallic materials.

This hybrid model has a spacious 38” x 24” working area and houses an optional 30 to 100-watt CO₂ laser and a 20/30/50-watt fiber laser. The dual-laser capability allows businesses to handle mixed-material projects, making it perfect for industries that need flexibility, such as promotional item producers and custom part fabricators.

The Spirit GLS Hybrid is equipped with the Real Pointer Alignment feature, which includes an additional beam combiner to align the red light pointer with the laser beam, enabling a what-you-see-is-what-you-get effect.

Designed for durability, it stands up well to frequent use, with a high-speed drive system that provides precise, intricate engravings on both metals and other materials. For applications that require versatility and reliable results, the Spirit GLS Hybrid delivers effectively.

The Spirit LS PRO, S400, and Spirit GLS Hybrid are all equipped with features designed to meet the demands of high-quality metal engraving. Whether you’re prioritizing the convenience of rapid positioning for production with the Spirit LS PRO, the speed and high-volume capabilities of the S400, or looking for multi-material flexibility with the Spirit GLS Hybrid, GCC LaserPro engravers provide dependable solutions for professional, lasting metal engravings across various industry needs.

Conclusion

Choosing a reliable laser engraving machine for metal ensures precise, durable engravings that stand the test of time.

With high-quality equipment like GCC LaserPro Spirit LS PRO, S400 and Spirit GLS Hybrid, businesses gain the advantage of speed, versatility, and consistent results. Investing in the right engraver allows you to meet varied project needs efficiently, making it a valuable asset across industries.