Frequently Asked Questions About Laser Engraving Machines | GCC: Laser Machines Leader Since 1989

In this article, we'll cover some knowledge before buying a suitable laser engraving machine. Here we go:

- What is a laser engraving machine used for?

- What materials are suitable for laser engraving?

- How long do laser engravers last?

- How much does a laser engraving machine cost?

- Why is a laser engraving machine so expensive?

- How much does a small laser engraver cost?

- Which GCC LaserPro laser engraver should I choose?

What is a laser engraving machine used for?

The versatility of the laser system means that it works on many materials, including wood, acrylic, plastics, stone, metals, etc. In particular, it is a great tool to add numbers, logos, images, and serial numbers to parts. Laser engraving is today a technology commonly used for producing promotional products like pens, signs, and displays, which makes laser engraving suitable for a variety of industries, such as signage and advertising, personalization and identification, gifts and promotions, post-press, apparel, and electronics industries.

One of the most noticeable applications is customization which is popular nowadays, like a wedding ring with a name on it. It is more effective than traditional engraving for small objects.

In the apparel industry, it is most common to use laser machines to directly engrave customized patterns on materials. It is also applied to heat transfer vinyl, especially thick or stretchable materials. The laser engravers cut quickly and accurately, thus replacing the traditional cutting method.

Find out more on our Applications.

What Materials Are Suitable for Laser Engraving?

Laser engraving on Metal:

Engraving on metals offers precise and permanent markings. It is commonly used for personalization, branding, and industrial applications.

Laser engraving on Wood:

Wood engraving with lasers provides intricate designs and precise detailing, making it popular for personalized gifts, signage, and artistic creations.

Laser engraving on Acrylic:

Acrylic is well-suited for laser engraving due to its smooth surface and excellent light transmission. It is often used for signage, displays, and decorative items.

Laser engraving on Rubber:

Rubber engraving is utilized in industries such as stamp making, prototyping, and custom product manufacturing. Laser-engraved rubber stamps offer incredible details and results.

Laser engraving on Glass:

Laser engraving on glass produces elegant and precise designs. It is commonly used for glassware customization, artistic glasswork, and awards.

Laser engraving on Leather:

Leather engraving adds a personalized touch to products such as wallets, bags, and belts. It allows for detailed patterns, logos, or text on leather surfaces.

Laser engraving on Paper:

Paper engraving with lasers creates intricate designs, cutouts, or perforations. It is utilized in industries like packaging, stationery, and invitation card production.

For more information, please read this article: Materials Compatible for Laser Engraving, Cutting & Marking

How long do laser engravers last?

There is no actual data on how long a laser engraving machine can last, but it is certain that regular and diligent maintenance of the machine as recommended in the user manual will extend the service life of the machine. This not only keeps your laser engraving machine up and running, but also saves you the cost and time of repairing the machine.

Check this article "The Suggestions for Laser Machine Maintenance", which provides 5 basic maintenance tips below to ensure stable and reliable high quality output and extend the life of your machine.

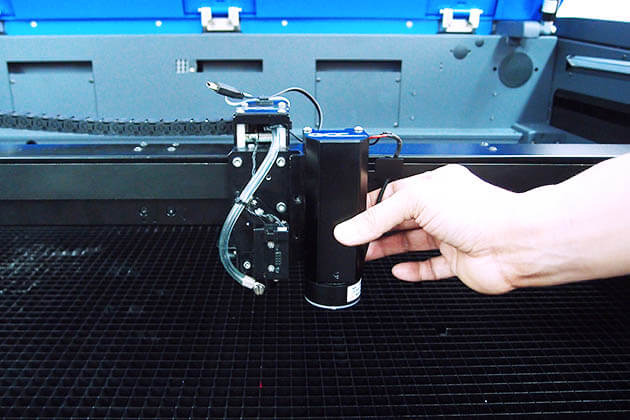

1. Cleaning the Worktable and Motion System

2. Lubrication of the X/Y Rail System

3. Cleaning the Mirrors

4. Cleaning the Focal Lens

5. Cleaning the Exhaust Duct

How much does a laser engraving machine cost?

Laser engraving machines are widely used in various engraving and cutting jobs because of the smooth cutting surface, fast cutting speed and high precision, especially in industries that have higher standards and requirements for cutting speed and accuracy. However, when buying a laser machine, people are likely to be confused as to which laser engraving machine to choose and what the price of the machine is.

It is difficult to give a simple answer as it depends on your needs or what kind of work you want to accomplish? Before starting all projects, you first need to consider the material you want to process and its production volume, and then you determine the specs you desire for the machine, such as the type of laser, wattage, and working area size. Different types of laser engraving machines have different functions and applications. Generally, the greater the wattage and work surface, the higher the cost.

Another thing to consider when buying a laser engraver is the cost of maintenance. The amount of cleaning required for machine maintenance depends on the materials used. Sometimes mirrors or lenses need to be finely cleaned, and the machine may also need to be realigned. Regular maintenance and cleaning help avoid consuming too much time and interrupting the company's production line. There is also the after-sales service, which may incur labor and parts costs when necessary.

With all of these having been taken into account, you just need to contact us, and we will help you choose the right model that suits your needs.

Why is a laser engraving machine so expensive?

The price of a laser engraving machine varies widely from one model to the next. There are some low-cost and self-assembled units available at US$100-300, but the limited efficiency and laser power can only handle paper or the surface of wood and plastic. However, there are some high-quality units that cost dozens of times or even more. This massive difference in equipment cost is reflected by the significant difference in machine quality, functionality, and performance.

High-quality laser engravers typically consist of durable components that do not break down easily and powerful lasers that cut through a variety of materials precisely and quickly. High-quality laser engravers use software that is compatible with many programs, making them highly versatile. Finally, it has a comprehensive warranty and service package that protects you from equipment malfunctions and breakdowns (usually lower-cost laser engravers are not provided with warranty and service and eventually given up).

While it may be tempting to buy the most inexpensive laser engraving machine so you can spend the least money on your latest beloved project, perhaps a more expensive machine is a wise investment for you in the long run. Investing more money into a higher-quality unit means longer service life and smaller maintenance costs, both of which will lead to lower overall equipment costs.

Regarding the high-quality laser engravers, you just need to contact us, and we will help you choose the right model that suits your needs.

How much does a small laser engraver cost?

Small laser engraving machines do not take up much space and therefore have a large market in DIY & hobby users, personalization, and education market. Small laser engraving machines in the market vary in quality and price. The price of a laser cutting machine is often determined by the laser brand, laser power, servo motor, laser head and other configurations. Of course, a more affordable system is by default less functional and perhaps less reliable, and the output quality does not always satisfy most people.

One thing to remind you is to consider practical needs rather than price when choosing laser equipment. There are a few factors to determine the suitable laser equipment for you, such as what materials you want to process, what you want the equipment for, and the quality you expect, etc.

Which GCC LaserPro laser engraver should I choose?

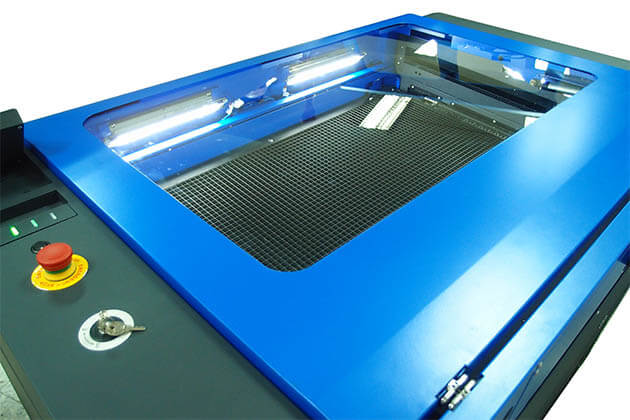

GCC LaserPro offers a diverse range of laser engraving options, from desktop to large format, including CO2, fiber, and dual-source options, with various table sizes. These machines are designed for easy maintenance, ensuring longevity.

The desktop models, E200S and C180II, are ideal for small items such as stamps, personalized items, or desktop accessories.

For elite models, we have the economical Mercury III and the MG380Hybrid, which combines metal and glass tube laser systems. Both are highly popular laser machines.

Our supreme models include the classic and versatile Spirit series, available in different sizes and wattages to meet your needs. Additionally, the large working area models, S400 and Piolas 400, are equipped with industrial processing capabilities to enhance productivity.

Unlike the CO2 laser machines mentioned above, the S290LS uses fiber laser technology, which allows it to engrave on metal.

Article by

GCC Product Marketing Team

GCC's dynamic product marketing team consists of professionals specializing in marketing strategy, content creation, and market analysis. They collaborate to conduct thorough market research execute targeted marketing campaigns, and work hand-in-hand with product development and sales teams to seamlessly connect technical features with customer benefits to bring breakthrough GCC products to market.

▶ 7 Tips for Making Rubber Stamps with Laser Engravers

▶ Laser Engraver Parameter Setup Methods for CorelDRAW, Illustrator & AutoCAD

▶ How Do You Maintain a Laser Engraver?

▶ GCC LaserPro Laser Engraver Print Driver Introduction