🆕 Piolas 400

用於訂製雷射雕刻寵物配件的 AI 3D 設計 | GCC星雲電腦提供電腦割字機、雷射雕刻機、雷射切割機、雷射打標機等專業設備

繁體中文

應用影片

雷射雕刻機

用於訂製雷射雕刻寵物配件的 AI 3D 設計

探索 GCC 雷射雕刻機在 MDF 上進行 3D 雕刻的創意潛力。了解如何使用 Adobe Firefly 的 AI 設計個性化寵物產品。獲取提示、設置和靈感,以最少的浪費進行精密雕刻。

Applicable Models

Details

在本月的 GCC 雷射應用實驗室中,我們將示範如何使用 GCC 雷射雕刻機在 MDF 材料上進行 3D 雷射雕刻應用。

步驟 1 造訪 https://firefly.adobe.com/

步驟 2 創建 AI 內容生成的描述

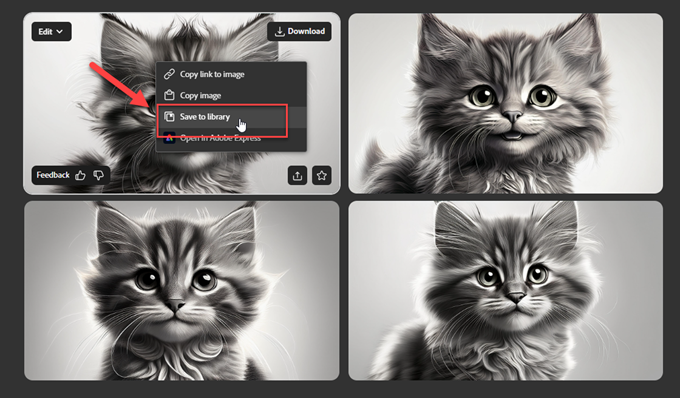

步驟 3 選擇要保存的圖片

本月的展示專注於客製化寵物產品的雷射切割和雕刻,使用 GCC 雷射雕刻機來創建所需的形狀和圖案。您可以使用 Adobe 的生成式 AI 工具 Adobe Firefly,通過輸入合適的描述來生成您想要的圖像。它提供多樣的風格和效果,即使沒有專業的設計技能,也能輕鬆上手。借助生成式 AI 工具和專業設計軟體,您可以編輯 AI 生成的圖片,應用灰階和抖動技術來創建精美的 3D 雕刻藝術作品。此外,GCC 雷射雕刻技術可應用於個性化的寵物產品,如客製化寵物項圈、名字牌、寵物肖像、杯墊等,為您的貓狗增添獨特且充滿心意的設計。這不僅讓您的創意構想成真,還提升了產品的精確度和美感,增加其價值。不論是個人定制還是工業應用,GCC 的雷射 3D 雕刻都是您的首選。

選擇 GCC 雷射雕刻機確保高精度、快速速度,並具備雕刻複雜形狀的能力,減少材料浪費並提高生產效率。無論您是在創作獨一無二的寵物配件,還是製作精細的工業產品,GCC 雷射雕刻機都能幫助您實現目標。

材料:MDF

| |

|  |

|  |

|  |

| |

建議參數:

| Spirit GLS | ||||||

| 類型 | 速度 | 功率 | DPI | PPI | 頻率 | 空氣 |

| 雕刻 | 15 | 100 | 600 | 400 | Y | |

| 切割 | 4 | 100 | 600 | 400 | Y | |

*以上參數僅供參考,應根據情況適當調整。