The disadvantages of die-cutting (ex., mold storage, noise) are now eliminated.

Our Partner COMNET interviewed Mr. Masahiko Mukoda, CEO of Upward Co., Ltd. He explained to us the reasons that he introduced the laser engraving machine, the applications thereof and the advantages of using it.

Company Name: Upward Co., Ltd

Major Business Items: Embroidery processing, patch production

Location: Osaka, Japan

GCC Products: GCC LaserPro Mercury III laser engraver (25W)

What issues did you have before introducing the laser engraving machine?

Our company manufactures embroidery patches and appliques. Before the introduction of laser engraving machine, we had used to cut out the fabric with molds.

As the number of molds increased with the new project, our workspace was overwhelmed by the molds and we ended up renting a warehouse dedicated to storing molds. Besides, it was also difficult for us to build complex shapes with metal molds.

*Installed model: The Laser cutter GCC series MercuryIII (25W)

What are the reasons for introducing the laser engraving machine, and what are the key points of selection?

We first learned about the laser engraving machine from a colleague. When a colleague saw our embroidery workload, he said "If you want to handle this much work, laser processing is the way to go" and then introduced COMNET to us.

After hearing about the convenience of laser engraving machine, I went to see it and found thatthe laser cutting could give a perfect cross-section to the fabric without fraying.

I thought "It's perfect for our company doing embroidery work" and then decided to bring in this laser engraver without hesitation, as the laser machine can also be ideally installed in a small space.

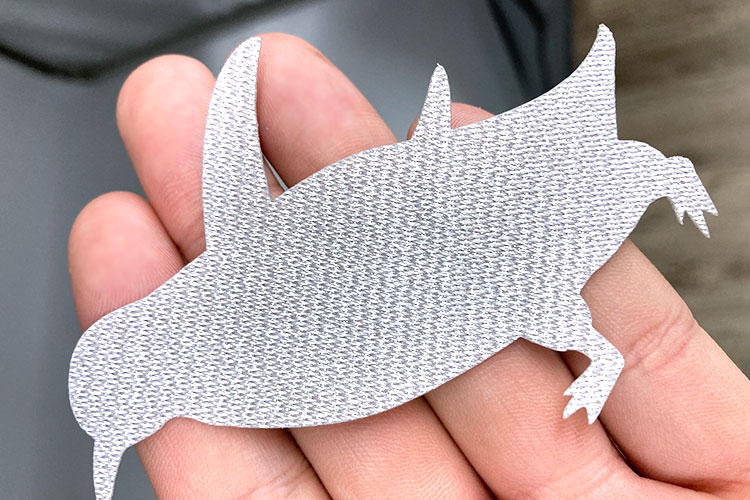

*Cross-section of laser-cut fabric. No fraying due to heat processing

What are the outcomes after the installation of the laser engraving machine?

Thanks to this, we are now able to do quite a few more applique jobs that other companies cannot do. In particular, we have managed to reduce the unit price of cloth applique to one-tenth of the unit price of embroidery; and our customers are very happy with this.

In addition, compared to molds, the laser engraving machine produces less noise and vibration, which is good. When we used molds to cut out the fabric, there was always a "bang" noise that echoed off the walls and bothered our neighbors.

After the installation of the laser engraving machine, we can now work with peace of mind even at night.

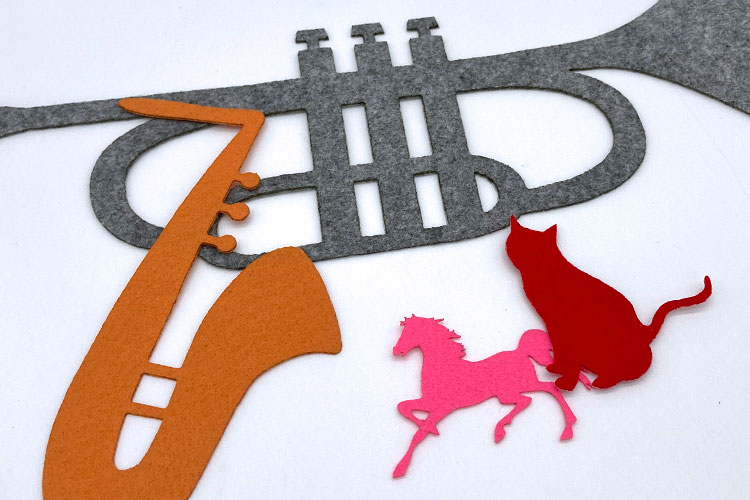

*Applique on cloth (woven fabric that looks like tatami sewn)

What are your future prospects for the laser business?

We installed a third laser machine at the beginning of 2022 and have gradually received more orders for acrylics and polyester in addition to fabrics.

We would like to further expand the scope of our work in the future.

To read the original article, please click here.

*Por favor, absténgase de reproducir o distribuir este artículo sin obtener permiso de GCC.