SmartEYES™ CCD is Your Time-Saving Tool to Boost Productivity | GCC: Laser Machines Leader Since 1989

The process of laser engraving and cutting is extensively used in the industry, and how to make the whole process more convenient and obtain accurate results has always been an important topic in product development. GCC LaserPro has been continuously researching and developing, and finally achieved the perfect combination, high performance S400 laser engraving machine with SmartEYES™ CCD, allowing users to quickly position and complete laser engraving and cutting to increase profitability.

Super Easy Work Flow

Open the top lid of S400 laser engraver, place the object on the working table, move the graphics to the place you want to engrave on the computer screen, press start button and your image will be engraved on the area where you want it to be. Users had to repeatedly confirm the position and test in the past, with SmartEYES™ CCD, in addition to shortening the workflow, you can also avoid the waste of materials due to modifications during testing.

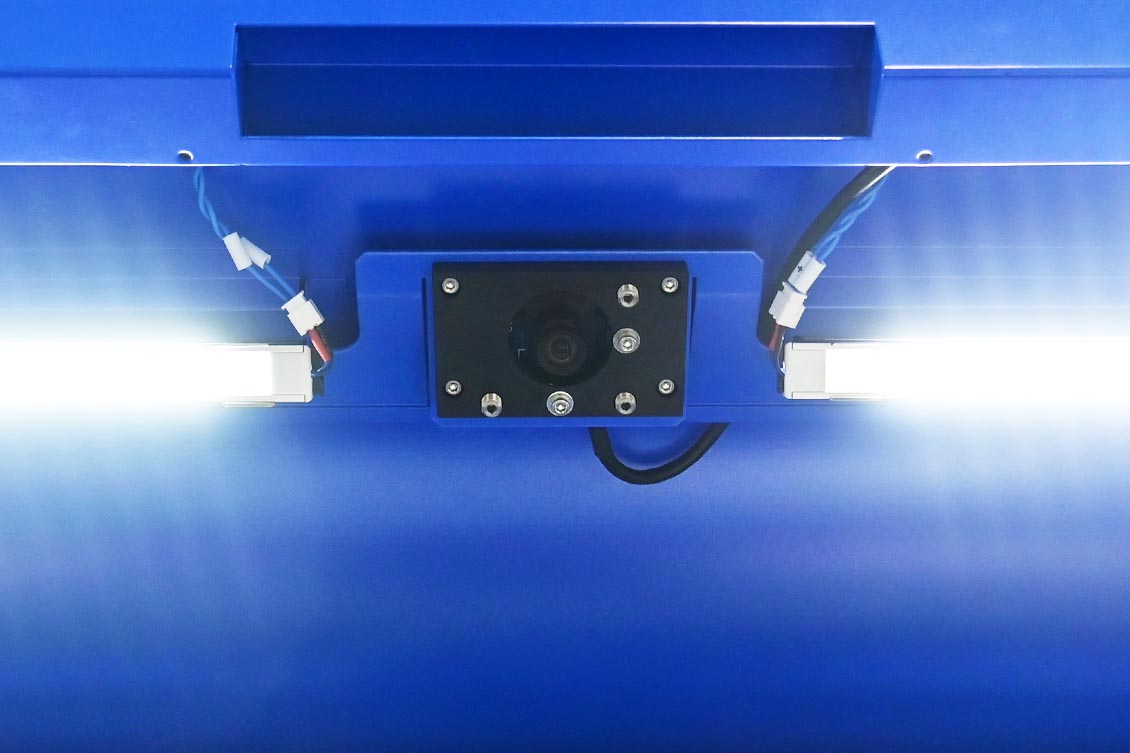

High Resolution Camera

The SmartEYES™ CCD is a super high resolution camera with real-time color image, which is located on the top lid to enable you to view the entire S400 laser engraver working area. You can resize and position your image, which means you can preview how the engraved image will look like on the object.

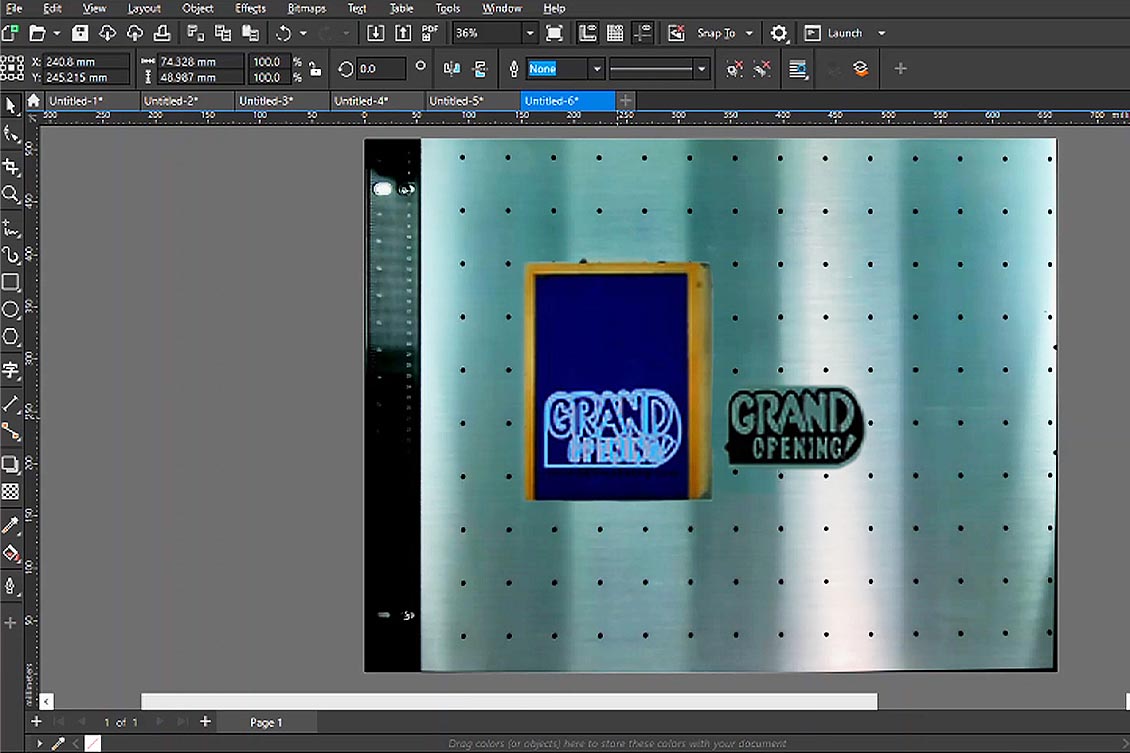

Integrate With Software

Users can import pictures into commonly used design software CorelDRAW/Illustrator through plug-in, which is convenient for users to quickly edit the graphics to complete positioning and laser jobs. It also can work with SmartVISION Pro CCD software, providing an easy workflow for print and cut applications.

The Perfect Combination

The S400 is the flagship model of LaserPro laser engravers and has won many reputations for its best design in terms of high speed, large working area, dust prevention technology, and dual laser source. Now the combination of S400 with SmartEYES™ CCD is a perfect match, whether doing laser engraving or cutting for short run process or mass production, your job can be done with much higher productivity to bring you more profit.