2024 Top-Quality GCC Laser Cutters & Cutting machines

In this article, we'll cover some knowledge about laser cutter. Here we go:

- What Is a Laser Cutter, and How Does It Work?

- What Can a Laser Cutter cut?

- How Much Is a Laser Cutter?

- What Types of Laser Cutter GCC Provides?

- Laser Cutter vs. Laser Engraver: What's the Difference?

- Laser Cutter Software

- GCC LaserPro Laser Cutting Machine Applications

- What materials cannot be cut on a laser cutter?

- How thick can a laser cutter cut?

GCC owns research and development technology and upholds the customer-oriented concept, continuously refining and developing professional Laser Cutting Machines, which not only have superb laser cutting quality but also win a good reputation in the industry. GCC LaserPro laser cutters are very convenient tools for prototyping and manufacturing. Apart from cutting, laser cutters can also engrave by heating the surface of a workpiece. In this guide, we will explain what laser cutters are, what they can do, and how to use them.

What Is a Laser Cutter, and How Does It Work?

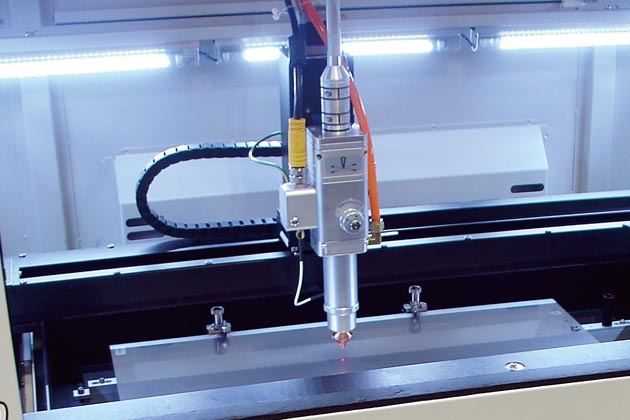

As its name implies, laser cutters are a tool used in a wide range of industries for precision cutting and designing projects. The laser cutting system sends out a beam of intense light through reflects through an array of mirrors to the lens carriage. And within the lens carriage, the laser is focused through a lens and narrowed down to an extremely concentrated beam. The high-powered laser beam is then projected down and used to either cleanly cut or engrave a specific design of patterns and geometries on materials.

Laser cutters are so fast that they can cut designed parts in just minutes, they are rapid prototyping machines; they allow designers to quickly and inexpensively transform their designs before they produce products on a larger scale.

Laser cutters are also a perfect multipurpose tool as they can be used to process and complete the production of different types of designs, making anything from cardboard prototypes to metal ornaments. The difference between the different types of laser cutting machines comes from the type of laser source. The type of laser source determines the properties and thickness of material it can cut, as different laser types have different power ranges.

Buy Laser Cutting Machines

What Can a Laser Cutter Cut?

The types of materials for laser cutting are mainly divided into metal and non-metal cutting. However, they depend on two different laser sources: CO2 laser and fiber laser. These two laser sources, CO2 laser and fiber laser, handle different materials and thicknesses when processing laser cutting.

● CO2 Lasers - Laser Cutter:

The use of CO² gas as a gain medium in the laser system characterizes CO2 lasers, which produce a beam of infrared light with the principal wavelength bands centering on 9.6 and 10.6 micrometers (μm). They are the most common types of CO2 laser cutters because they are low-power, relatively inexpensive, efficient, and can be used to cut through various types of materials. The lower-power lasers are used to cut a variety of thinner, potentially flammable materials like paper, wood, and high-power lasers can cut plastic with high thicknesses such as 25 mm acrylics, referred to Wikipedia.

*Material: plywood, veneered wood, acrylic, leather, paper/card, EPE Foam, plastic/film and some fabrics.

● Fiber Lasers - Laser Cutter:

Fiber lasers are formed from a solid fiber-optic cable doped with rare earth metals as their gain medium. The wavelength of fiber lasers is 1.06 micrometers (μm), this smaller wavelength is much better suited in general to cutting metals as more of the beam’s energy is absorbed into the material and less is reflected. These fiber lasers have higher intensity and therefore cut through much thicker materials.

*Material: gold, silver, copper, brass and aluminum

As different laser types are involved in the construction and design of the laser cutting machine, usually, one laser cutting machine is equipped with one laser. If you want to process both metal and non-metal materials, you can check out our dual laser source laser cutter model, the S400 laser engraver and Spirit GLS hybrid laser engraver, a combination of CO² & Fiber laser, it's all here in one and will save on space! The processed materials are compatible with metal & non-metal cutting and engraving and are both popular laser cutting and engraving machines with high quality and throughput.

How Much Is a Laser Cutter?

An ideal laser cutter can cost anywhere from $500 to $20,000, or more if it's an industrial laser cutter. Prices and costs of laser cutting machines fluctuate greatly depending on the design, type, and power of laser. In general, the higher the laser power, the higher the laser cutter machine price, and therefore the better it can cut through materials.

Entry-level laser cutting components usually contain relatively weak lasers that are only suitable for light engraving or cutting. Employing a laser cutter with an underpowered laser to cut a thick or hard material can ruin the surface, requiring expensive material replacement. If you plan to cut thick materials, you’ll need a higher wattage laser cutter which with a higher cost. The GCC LaserPro X series CO2 laser cutters are exactly the solution, they use glass tube lasers and come in a variety of wattages from low to high, even if you end up needing higher wattage prices are affordable.

If you plan to cut metal, you will need a much higher wattage than the laser cutters mentioned above. A metal laser cutting machine can cost from $8,000 to over hundreds of thousands, especially those for industrial use, which are bulky and ultra-high wattage and can be worth a fortune. If you are considering a metal laser cutter that does not take up a lot of space and can handle customized products, the GCC LaserPro FMC 280 fiber laser cutter is the machine right for you. Designed specifically for metal cutting, the FMC 280 fiber laser cutter not only does not hog the entire workshop but can also handle very small & low volume projects.

In addition, cutting larger objects will require a laser cutting machine with a large working table, which is also a price-related consideration. Buying a high watt laser cutting machine can be cost-effective for prolific cutters. If you do not know what you intend to cut, or want to cut a wide variety of materials, it is best to purchase a high wattage laser cutting machine. This type of laser cutter is strong enough to cut and engrave almost anything, and GCC LaserPro offers versions of the best laser cutters in a variety of sizes to give you the flexibility you need.

What Types of Laser Cutter GCC Provides?

Laser cutting is a very common application in processing. In order to meet the various cutting needs, whether it is non-metal materials or metal materials, cutting and engraving, or different working areas, GCC builds various laser cutting machines with continuous innovations in research and development, the following is the introduction of the GCC LaserPro laser cutters.

CO2 LASER CUTTING MACHINE

X252 CO2 Laser Cutter

Specifications:

- Working Area: 635 x 458 mm (25 x 18 in.)

- Z-axis: 165 mm (6.5 in.)

- Wattage: 80W~100W

- Speed: 40 IPS

Reasons to Buy:

- Economical equipment, suitable for beginners to start

- Closed-loop DC servo control for precise and rapid movement of the lens carriage

- Pass-through doors to accommodate oversized objects

Product Description:

The GCC LaserPro X252 CO2 Laser Cutter offers an economical alternative for laser cutting and engraving. X252 CO2 Laser Cutter dependable sealed CO² laser which offers a reliable source of 80W and 100W of power for mass production requirements.

X380 CO2 Laser Cutter

Specifications:

- Working Area: 960 x 610 mm (38 x 24 in.)

- Z-axis: 165 mm (6.5 in.)

- Wattage: 80W~100W

- Speed: 40 IPS

Reasons to Buy:

- Equipped reliable DC CO² glass laser tube makes it an economical choice

- Closed-loop DC servo control for precise and rapid movement of the lens carriage

- Pass-through doors to accommodate oversized objects

Product Description:

The GCC LaserPro X380 CO2 Laser Cutter is equipped with dependable sealed CO² laser which offers a reliable source of laser power for mass production requirements. GCC LaserPro users always have an edge over the others with numerous uniquely innovative and user friendly features.

X500III Pro CO2 Laser Cutter

Specifications:

- Working Area: 1300 x 916 mm (51.1 x 36.1 in.)

- Z-axis: 48.26 mm (1.9 in.)

- Wattage: 100W~150W

- Speed: 40 IPS

Reasons to Buy:

- Equipped reliable DC CO² glass laser tube makes it an economical choice

- 1.6X beam expander for uniformity of line width and spot size

- Fulfill versatile cutting and engraving applications

Product Description:

Embrace the cutting technology from the LaserPro X500III Pro CO2 Laser Cutter designed and engineered for professional use. GCC releases X500III Pro CO2 Laser Cutter version for advanced cutting quality and uniformity of line width by adding one beam expander and red beam combiner. Packed with several user-friendly features, the X500III Pro CO2 Laser Cutter offers high product performance in terms of both durability and feasibility.

T500 CO2 Laser Cutter

Specifications:

- Working Area: 1300 x 905 mm (51 x 35 in.)

- Z-axis: 127 mm (5 in.)

- Wattage: 60W~200W

- Speed: 40 IPS

Reasons to Buy:

- Up to 200W output power can cut through 1”(25mm) acrylic

- AC servo motor technology for precise movement control

- Excellent engraving quality with 3D capacity

- AAS module performs automatic graphic contour tracking task

Product Description:

Developed on the basis of GCC LaserPro’s accumulated technology with new powerful motion system, T500 CO2 Laser Cutter is capable of exceptional 3D laser engraving quality and cutting at high speed which make it a high ROI laser system on the market. Equipped powerful 200W laser tube allow user to deliver clear and fine cutting result. GCC Laser Pro T500 CO2 Laser Cutter is a dedicated design to fulfill your cutting and engraving needs in one machine with high throughput and superb quality.

FIBER LASER CUTTING MACHINE

FMC 280 Fiber Laser Cutter

Specifications:

- Working Area: 712 x 370 mm (28 x 14.5 in.)

- Z-axis: 120 mm (4.7 in.)

- Wattage: 1.5kW peak power

- Speed: 20 IPS

Reasons to Buy:

- State-of-the-art fiber laser technology to cut up to 3mm thick stainless steel

- Achieve 256 level grayscale, vivid image engraving

- Compact and robust design does not take up the entire workshop

- Multiple optional items such as Rotary Chuck to meet various needs

Product Description:

Compact size high power fiber laser cutting and engraving system, GCC LaserPro FMC 280 Fiber Laser Cutter delivers an easy way to operate fiber laser cutting which yields spectacular cutting edges. The FMC 280 Fiber Laser Cutter is a cutting specialist engineered for performance and produces excellent output quality, which is the best laser cutter for you.

Laser Cutter vs. Laser Engraver: What's the Difference?

Laser cutter and laser engraver are more or less used as synonyms, because most laser machines can perform both processes, cutting and engraving. Although both work on the same principle, it mainly depends on the actual requirements of the user. GCC LaserPro distinguishes them into laser cutters and laser engravers based on their primary usage. If the laser is primarily used for cutting, it is usually referred to as a laser cutter. If engraving is the main application, then it is called a laser engraver.

Simply put, if you are looking for a lifelike engraving effect, you can choose a lower wattage metal tube laser engraver to achieve the best engraving effect. If the main purpose is to cut different thicknesses of materials, we would recommend a higher wattage glass tube laser cutter for a faster process of thick materials.

The GCC LaserPro MG380 Hybrid Laser Cutter with both a metal laser tube and a glass laser tube is the model that meets this need, this enables a switch between the RF driven metal tube and high powered DC excited CO² glass tube within one second, to deliver extraordinary engraving effects and produce a clear cutting edge.

MG380Hybrid CO2 Laser Cutter

Specifications:

- Working Area: 960 x 610 mm (38 x 24 in.)

- Z-axis: 165 mm (6.5 in.)

- Wattage: 12W~100W

- Speed: 40 IPS

Reasons to Buy:

- Closed-loop DC servo control for precise and rapid movement of the lens carriage

- Dual laser tube for great laser cutting and engraving job

- Pass-through doors to accommodate oversized objects

Product Description:

The GCC LaserPro MG380Hybrid CO2 Laser Cutter is equipped with RF driven and DC excited dual CO² laser tubes at the same time which allow user to produce superior cutting and engraving work piece. All in one machine save your storage space and make your profit maximum. The GCC LaserPro users always have an edge over the others with numerous uniquely innovative and user friendly features.

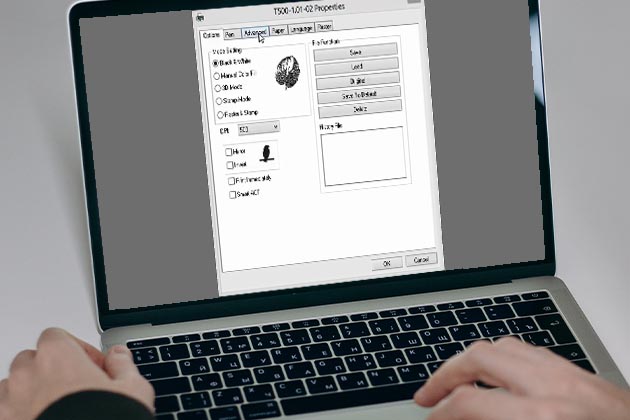

Laser Cutter Software

There are many different types of software that are commonly used to design graphics files for laser processing, which include text logo design, graphic design, and layout, photo editing, CAD/engineering design.

As mentioned earlier, GCC LaserPro laser system does both cutting and engraving, so it is applicable to software such as CorelDRAW, AutoCAD, Adobe Illustrator, Inkscape, Adobe Photoshop, and so on. Keep that in mind before you come to execute laser cutting and engraving, vector artwork that has all text converted to curves or outlines. As for the bitmap, the higher the quality of the graphic you're working with, the better your engraving results.

SmartPRINT™

GCC LaserPro has developed our own software SmartPRINT™ to facilitate the process for laser cutting and engraving. SmartPRINT™ features powerful functions, an intuitive interface, and built-in GCC LaserPro laser parameter setting for both Mac and Windows users. SmartPRINT™ provides clipart libraries, compatibility for various file formats, and advanced graphic functions such as Auto Trace Image Contour, Convert to Rhinestone, Generate Puzzle, and many more. Also, the additional text justification and sizing options can convert stroke to the path.

GCC LaserPro Laser Cutting Machine Applications

We are happy to answer your questions about any laser products and processing. If you want to learn and do more with GCC LaserPro laser cutters, we invite you to see our laser cutting applications videos where you will find out how they physically work and are done.

What materials cannot be cut on a laser cutter?

Laser cutters are incredibly versatile tools, capable of cutting through a diverse range of materials. However, there are specific materials that are not suitable for laser cutting due to various reasons. Some materials that generally cannot be cut on a laser cutter include:

Metals:

Laser cutters work by using a super powerful beam of light to melt or vaporize materials. But metals are just too tough for them to handle. However, the GCC LaserPro FMC280 laser cutter uses a higher-power fiber laser, enabling effortless cutting of thin metal sheets.

Reflective Materials:

Highly reflective materials like mirrors or some metals can reflect the laser beam back into the machine, the laser beam gets all confused when it hits a mirror and can bounce back in unexpected ways, causing damage to the laser cutter.

TIPS: If you want to do laser engraving on the mirror, you can consider doing it from the backside (the side with a thin coating). As for mirror-like metal, the GCC LaserPro FMC280 laser cutter is a good choice with its capacitive cutting head to avoid reflections.

PVC and Vinyl:

Cutting these materials can release toxic gases, which are harmful to both the machine and the operator. So, it's best to find another way to work with PVC pipes and we recommend GCC vinyl cutters to deal with vinyl sheets.

Foam:

Refers to any foam material, including rubber or plastic. When exposed to the heat of a laser, the foam material may catch fire, melt, or, as mentioned earlier, produce toxic gases.

In conclusion, when laser cutting any material with a plastic texture or coating, it is essential to use the Fume Extraction System along with proper ventilation and safety precautions. This ensures the safety of both the operator and the machine.

How thick can a laser cutter cut?

The cutting performance of a laser cutting machine depends on the wattage. The thicker the material, the greater the wattage required. Additionally, the thicker it is, the longer it takes.

In the case of the GCC LaserPro with a high-wattage laser cutting machine, the X500III Pro laser cutter is capable of cutting through 20mm acrylic, while the T500 laser cutter can cut up to 25mm. Both machines can achieve smooth cutting surfaces and clear-cut edges with a single pass, and they can also cut through 15mm MDF.

In addition, the FMC280 laser cutter, which is specially designed for cutting metal, can cut 3mm thick stainless steel and is also a stand-alone metal laser cutting machine that does not take up space.

Article by

GCC Product Marketing Team

GCC's dynamic product marketing team consists of professionals specializing in marketing strategy, content creation, and market analysis. They collaborate to conduct thorough market research execute targeted marketing campaigns, and work hand-in-hand with product development and sales teams to seamlessly connect technical features with customer benefits to bring breakthrough GCC products to market.