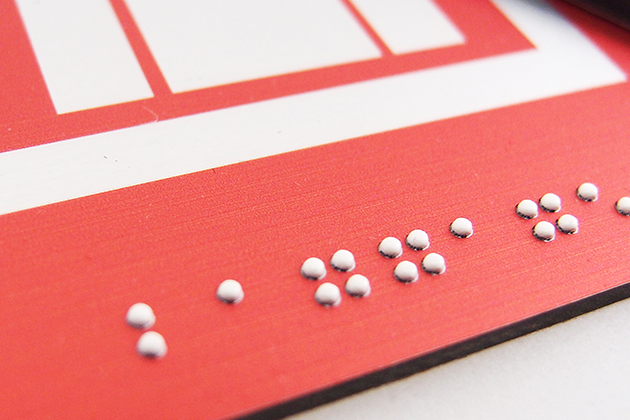

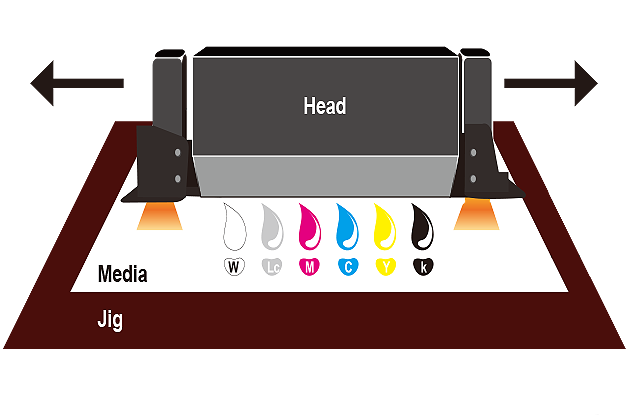

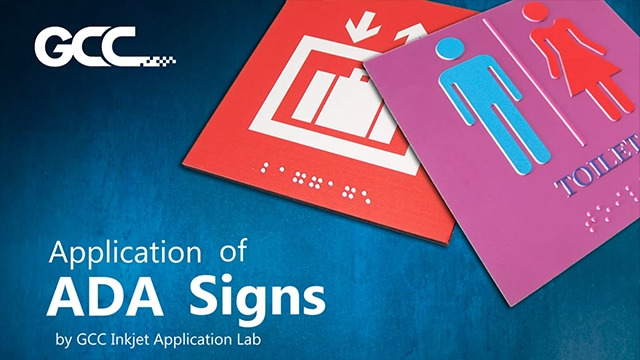

Built-in ADA Printing Function

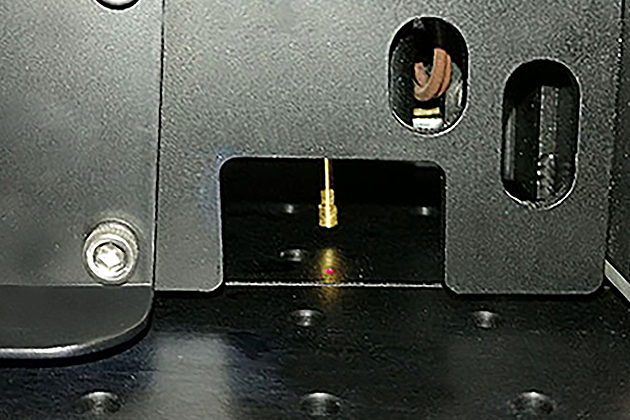

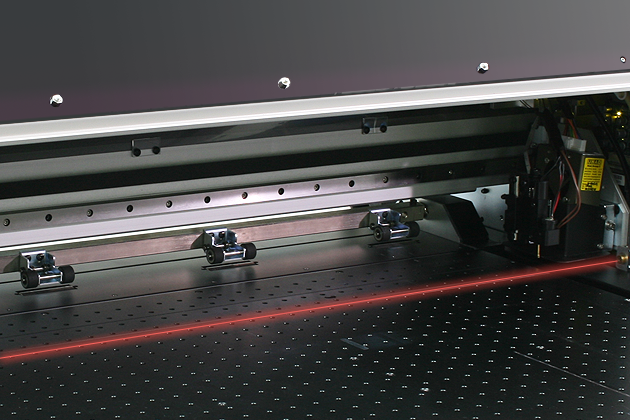

With the specially-developed ADA printing technology, JF-240UV can produce ADA signs with one simple printing process. JF-240UV provides the best solution for ADA-compliant sign printing in a wide range of applications.